Precision Dyeing, Perfect Results

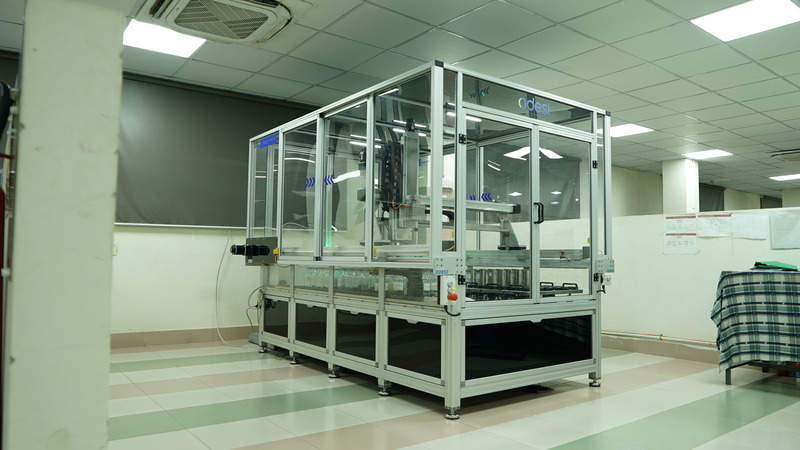

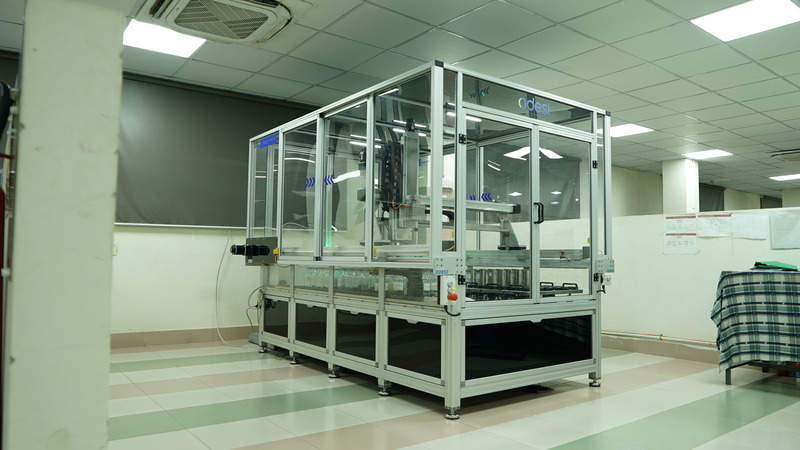

At Savartex, our dyeing unit is equipped with a comprehensive range of high-efficiency dying machines to ensure precision, flexibility, and premium fabric coloration across all product categories. We proudly operate a fleet of 11 advanced dyeing machines, sourced from globally trusted brands such as DANITECH and CANLER, offering a total capacity of over 20000 kg per day.

Savartex’s in-house dyeing facility combines high capacity with precision and sustainability. With machines ranging from 10 kg to 1,500 kg, we support both bulk production and sample development. Our setup handles a wide variety of fabric types and weights, ensuring flexibility and efficiency.

Up to 1,500 kg for bulk production

10–50 kg for R&D and development trials

Enabling processing of various fabric types and weights

Aligned with our sustainability goals

Up to 1,500 kg for bulk production

At Surma Garments Ltd. – Unit 2, we take pride in maintaining world-class quality standards with our fully equipped in-house testing laboratory, supporting both physical and chemical evaluations. Our testing capabilities ensure that every product we deliver meets rigorous international standards and buyer-specific requirements.

We conduct comprehensive fabric and garment performance tests using globally recognized methods

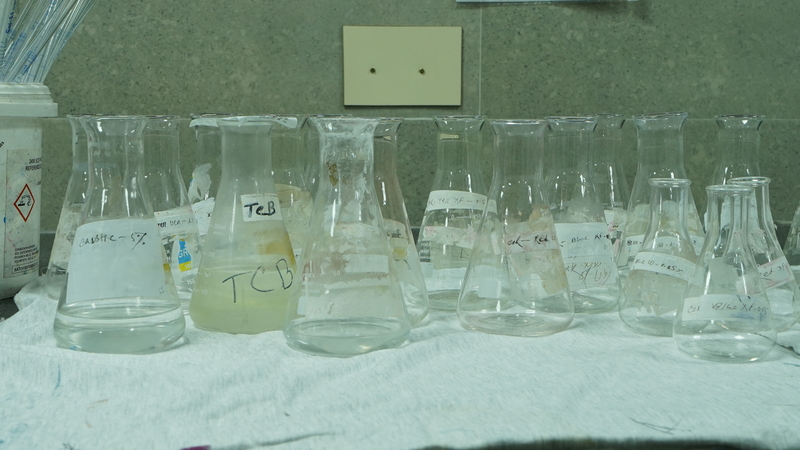

Empowering Quality Through Precision – Savartex Laboratory Division Savartex is equipped with a wide range of modern laboratory instruments to ensure fabric quality, color accuracy, shrinkage analysis, dye performance, and compliance with global standards. Our in-house testing facilities support R&D, bulk production assurance, and customer-specific requirements.

Our lab ensures real-time quality control, buyer compliance, and sustainable testing practices that align with global certifications and brand expectations.

Our chemical analysis lab ensures fabric safety and process optimization through

Empowering Quality Through Precision – Savartex Laboratory Division Savartex is equipped with a wide range of modern laboratory instruments to ensure fabric quality, color accuracy, shrinkage analysis, dye performance, and compliance with global standards. Our in-house testing facilities support R&D, bulk production assurance, and customer-specific requirements.

Savartex © 2025-26